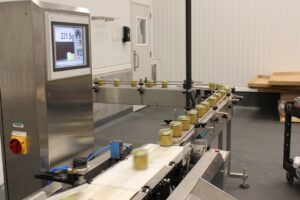

In-motion checkweighing is an essential part of any modern production line.

Checkweighers are an essential component of any production line, providing an accurate weight assessment of every product. In the past, static checkweighers may have been more common. These devices require hands-on interaction to move the product on and off the scale. Today, modern checkweigher manufacturers such as AP Dataweigh, Inc. are providing facilities with in-motion checkweighers that automatically weigh products as they move through the production line at high speed. In-motion checkweighing is a modern evolution of the packaging industry that provides excellent accuracy without sacrificing time and speed. Read on to learn more about what makes an in-motion checkweigher and why we prefer in-motion to static checkweighing.

The Advantages of In-Motion Checkweighing

While static checkweighing is very low-maintenance and has a lower initial cost, it is really only useful for small production facilities. However, if you need to weigh many items in a short period and guarantee accuracy, in-motion checkweighing is best. When you use in-motion checkweighers you:

- Decrease operator time

- Experience fewer manual errors

- Increase productivity through the use of automation

- Ensure a 100% inspection rate

Four Primary Components of an In-Motion Checkweigher

A few components are essential for the efficient in-motion checkweighing you expect from your machinery.

Conveyor Belts

Infeed and outfeed conveyor belts move your products through the checkweigher and along your production line. Checkweighers are integrated into your pre-existing production line, so the conveyor belts can be customized to fit your needs.

Weight Indicator

The indicator, or controller, is what displays advanced weight functions and serves as the command center for all calibration and operation. Indicators show real-time monitoring of your pre-set weight zones and permit viewing and printing of reports.

Load Cells

Load cells come in different types, but all serve the same purpose: accurately measuring weight on a scale. When weight is placed on the scale, the load cell takes a measurement and converts it to a digital output. Load cells are typically aluminum or stainless steel.

Accessories

There are numerous accessories you can add to your in-motion checkweigher. From reject devices to barcode scanners and labelers, your machine manufacturer at AP Dataweigh, Inc. can discuss your options with you and design a custom machine suitable for your production line.

Contact AP Dataweigh, Inc. For Customized Checkweighing Solutions

Established in 1994, AP Dataweigh, Inc. is a checkweigher manufacturer offering a complete line of custom-built and dynamic checkweighers and inspection system solutions. Our American-made machines address the needs of the pharmaceutical, agricultural, food, and industrial product markets throughout North America. We manufacture our machines to exact customer specifications and design them to integrate into your production line. What distinguishes us from the competition? We make what customers need instead of trying to sell what we make.

To learn more about the products we can provide for your facility, contact us online or by phone at 678-679-8000. You can also follow us on Facebook, LinkedIn, Twitter, and YouTube for updates on our products and industry.