The Problem:

A leading provider of commemorative coins was having difficulty accurately and efficiently weighing 1 oz. silver coin blanks. Regulation requires no coin can weigh below 1 oz. and any amount over 1 oz. cannot be charged to a customer and comes straight out of profit. Three technicians manually hand weighing samples on a random basis was labor intensive and inaccurate leading to significant silver give away.

The Solution:

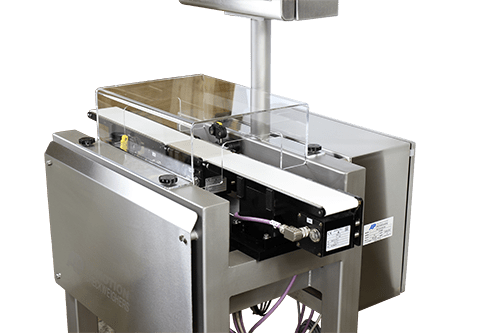

AP Dataweigh, Inc. recommended our High Resolution Checkweigher with a built in reject. During the factory acceptance test, AP Dataweigh was able to adjust the accuracy down to 0.05 grams with repeatable results.100 % of all silver blanks can now be tested with minimal labor. Rejected blanks (both over and underweight) are now captured, melted down and remolded, instead of being processed “as is” and sold for less than they are actually worth!

The Payback:

100% of all silver blanks are now tested by only one technician resulting in labor savings of $60,000/year. Silver loss through previous overweight give away has been reduced by 0.5% resulting in annual savings of $70,000/year. Now 100% of all coins are guaranteed to meet minimum weight.

- Savings – $130,000/year

- Investment – $32,000

- Payback – 3 months

Most production facilities are aware of the necessity of having the weight of their product match the label, in order to prevent underweight products from shipping to customers, but overlook the potential impact of overweight products.

Have you thought about using a checkweigher to manage an acceptable upper limit of your product as well? Let AP Dataweigh, Inc.provide you with a custom checkweighing system capable of rejecting OVER as well as underweight products.Treat your product like the precious metal it is. Let AP Dataweigh, Inc. make sure your profits are not going out the door, and stay where they should be – in YOUR pocket!